STRETCH SMARTER:

How G7 Film Redefines Efficiency & Sustainability

Why G7 is the Future of Stretch Film

In today’s fast-paced packaging world, efficiency, sustainability, and performance are non-negotiable. That’s where G7 Ultra High-Performance Stretch Film comes in. Engineered to deliver maximum load containment with minimal material use, G7 is transforming how companies wrap, ship, and save.

Whether you’re using hand wrap or high-speed automation, G7 adapts to your operation— cutting waste, reducing costs, and improving load security without requiring equipment changes. This guide explores how G7 fits into the broader stretch film landscape and why it’s the smart choice for modern packaging.

Why G7 Matters

More than Ever

Your product’s journey doesn’t end at the production line—it ends when it reaches your customer intact.

G7 helps ensure that happens by:

- Increasing load retention without increasing film thickness

- Reducing film usage through superior stretch performance

- Lowering carbon emissions and plastic waste

- Performing consistently across different machines and locations

Download our eBook Today!

Our guide is an invaluable resource for your team. It helps address common questions and overcome objections when selecting the perfect stretch film for various tasks. Keep this eBook handy to ensure you always make informed decisions.

WHY DOES USING THE CORRECT STRETCH FILM MATTER?

All that hard work to make a great product can go to waste if it doesn’t reach your customer in the right condition. The stretch film you choose plays a key role in how well your product holds up during transit.

It starts with understanding the basics of application

and film selection. Choosing the correct stretch film:

- Keeps products intact

- Speeds up wrapping

- Cuts waste

Different stretch equipment, load type, weight and speeds require specific film types, and the wrong match can lead to:

IPG offers high-quality cast and blown films for both hand and machine applications, with options engineered for:

Lighter gauges like G7 and Genesys Ultra reduce waste without sacrificing strength, while hand wraps like Prolite and Orbit Air B make manual wrapping easier and more secure.

Whether you ship heavy or irregular loads, choosing the right film keeps your operation efficient and your products safe. Keep this in mind so you can make the ideal decisions for your business.

THE (BRIEF) HISTORY OF STRETCH FILM

Stretch film has been used for decades, quickly rising in popularity as a practical and protective solution for shipping and storage. Its ability to shield products from dust and moisture made older palletizing methods obsolete.

Early versions were hand-applied, requiring no equipment. However, many dispensers were later developed to make the process easier.

Hand Wrap

Hand-applied stretch film is usually pulled using both hands and stretched around 50% to 80% before being secured to a pallet. This method works well for smaller operations or low-volume shipping needs. As automated software for wrapping equipment became more common, stretch film technology advanced to keep up.

Manufacturers developed stronger, more elastic films designed to handle the higher speeds and greater stretch capabilities of modern machines.

These new films:

- Offer better load containment

- Reduce film waste and achieve a lower carbon footprint

- Increase efficiency in high-volume environments

Machine Film Applications

Machine-applied stretch film is typically used with a rotating turntable wrapper, allowing the film to stretch from 100% to over 300% during application. This method not only speeds up the wrapping process but also reduces material use. Thinner films or stretched further, helps to reduce:

- Plastic consumption

- Operator effort

- Environmental impact

As machines became more advanced, film manufacturers had to keep pace. They responded with:

- Tighter gauge control

- Multi-layer construction

- Better winding techniques

KEY TERMS TO KNOW

Understanding stretch film starts with knowing the right terminology.

These terms explain:

- How the film performs

- How it’s applied

- What makes one option better than another

The stretch rate refers to how much the film is stretched between the first and second rollers in a pre-stretch wrapper. It’s usually expressed as a percentage based on how far the film is pulled - stretching from 10 inches to 20 inches equals a 100% stretch rate. The stretch rate helps determine how much film you’re using and how tightly it’s applied to the load.

F1, or stretch force, is the amount of force needed to stretch the film to its target stretch rate. This tension is created between the two rollers in a prestretch mechanism. Knowing the F1 value helps ensure your equipment and film are calibrated to work efficiently together.

On-Pallet Stretch, or OPS, measures how much the film stretches as it’s applied to the load. For example, stretching 10 inches of film to 20 inches means you’re applying 100% OPS. It’s a key factor in understanding how much tension is being added during the actual wrapping process.

On-Pallet Stretch, or OPS, measures how much the film stretches as it’s applied to the load. For example, stretching 10 inches of film to 20 inches means you’re applying 100% OPS. It’s a key factor in understanding how much tension is being added during the actual wrapping process.

Stretch film has a built-in memory that makes it want to snap back to its original shape after stretching. This quality is what keeps the film tight around the pallet after application. Even if the load shifts or leans, the film stays snug, thanks to this elastic pull.

Load retention measures how well the film holds its shape and tension after it’s been wrapped. It reflects how much “memory” remains in the film over time.

High load retention means your product is more likely to stay secure during transport and handling. Each of these elements plays a role in creating a wrapped pallet that holds firm during transit without putting too much pressure on the product itself.

Striking the right balance is essential. The best way to get it right is by working with your equipment or film supplier to dial in the performance you need.

THE PROS & CONS OF USING THE RIGHT FILM

Choosing the correct stretch film can make or break how well your product travels. Let’s explore some of them in detail below.

Using the right stretch film can significantly cut down on waste by allowing you to use less material without sacrificing performance. It also helps lower labor costs by improving wrapping efficiency and reducing the time spent per pallet. Over time, the savings add up across:

- Film usage

- Damaged goods

- Operational downtime

The correct film provides consistent tension and load containment, preventing products from shifting or falling during transit. This reduces the chance of:

- Returns

- Customer complaints

- Lost revenue due to damaged goods

- Aligned

- Clean

- Intact from your floor to the customer’s dock

Using the wrong stretch film often leads to:

- Over-wrapping

- Frequent film breaks

- The need for rework

All of these can drive up costs. Even a single incident can prove to be a major issue in the future.

It can also result in excess plastic use, which adds both expense and environmental impact. Poor film performance means:

- More time

- More material

- Less efficiency

A film that doesn’t hold properly can lead to loose loads that:

- Shift

- Lean

- Collapse in transit

EXAMPLES OF STRETCH FILM IN ACTION

A real-world example of stretch film performance comes from a customer who replaced their original film with IPG’s G7 Ultra High-Performance film. Without changing their equipment, they increased load retention from 12.7 lbs to 15.0 lbs on one machine and from 18.3 lbs to 22.6 lbs on another.

This upgrade reduced annual film usage by 153 rolls across both machines and cut carbon emissions by over 12,000 pounds. Costs dropped by more than 20%, proving that thinner, high-performance film can outperform heavier options. The G7 film worked seamlessly across different machines and locations, showing its versatility and value.

TIPS & REMINDERS FOR STRETCH FILM

- Load type

- Weight

- Wrapping volume

These factors determine whether hand wrap or machine film is better and what gauge you need. Avoid using heavier film than necessary, as it adds cost without benefit. For machine applications, make sure your prestretch settings are correct and consistent to avoid wasted film or unstable loads. Hand wrapping should apply even tension without over-stretching, which can lead to tearing or loose wraps.

Store your film in a clean, dry area to preserve performance. Direct sunlight, dust, and moisture can all degrade quality over time.

Regularly inspect your equipment to catch wear and tear that may cause film breaks or uneven wraps. Always track your results by

looking for:

- Shifting loads

- Film breaks

- Excessive usage

Those are signs that your setup needs adjustment. If in doubt, work with your supplier.

They can help you fine-tune your process and choose the film that meets your needs without overdoing it. Small changes can make a substantial impact on:

- Cost

- Consistency

- Customer satisfaction

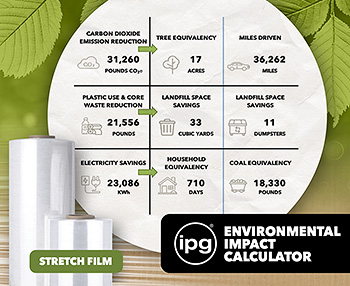

ANALYZING USING IPG’S STRETCH EVALUATION TOOL

IPG’s Stretch Evaluation Tool uses your specific pallet dimensions, wrapper settings, and load retention via the Lantech CFT-6 tool to evaluate different film options and application methods. Often referred to as a “Cut-and-Weigh” analysis, our tool takes the input data and automatically compares the current wrapping to Proposed and Optimized versions, using the same or upgraded films. Once the data entry is complete, the Analysis and Sustainability pages will provide you with ...

- Rolls and Costs saved Annually

- Loads per Roll

- Containment before and after

- Cost per Pallet

- Carbon reduction

- Waste reduction

- Electricity saving

Armed with accurate stretch data, companies can reduce costs and waste to apply, and avoid product damage. The tool works with any type of stretch film.

RESOURCES FOR STRETCH FILM

Finding the right stretch film means knowing where to look for help. Equipment manuals and usage guides can help you understand performance capabilities and limitations. Your film

supplier should offer hands-on support, including:

- Load testing

- Cost analysis

- Application advice

Industry blogs and case studies can also highlight how others solve similar challenges. It’s worth exploring new tools like mobile apps or digital calculators to track usage and improve efficiency.

If you’re working with automation, technical support from your machine’s manufacturer is key. The right resources:

- Save money

- Reduce waste

- Improve wrap quality over time

WORK WITH IPG TODAY

We offer a complete line of stretch film designed to meet the demands of any shipping environment. If your product moves from point A to point B, we have the tools to keep it secure.

IPG helps you reduce costs, cut waste, and improve packaging performance with advanced film solutions and automation. Backed by expert support and proven results, our products are built to keep your operation efficient and your shipments protected from start to finish.

Visit our website today, call 1-888-898-7834, or contact your area IPG representative to start lowering costs, improving packaging quality, and reducing your environmental impact.